provide a rapid/urgent response to spills.include periodic deep/comprehensive cleaning.have routine daily cleaning conducted during quiet/slow periods.It is also noted that flooring that is slip resistant can be cleaned to be as hygienic as other flooring. For example, the time detergent is on the floor has been shown to have a significant effect on cleanliness. are tailored to the specific flooring and contaminants – i.e.

are based on advice from the flooring supplier.maintain the slip resistant properties of the floor/surface (if non-slip flooring).do not leave a build-up of cleaning products.

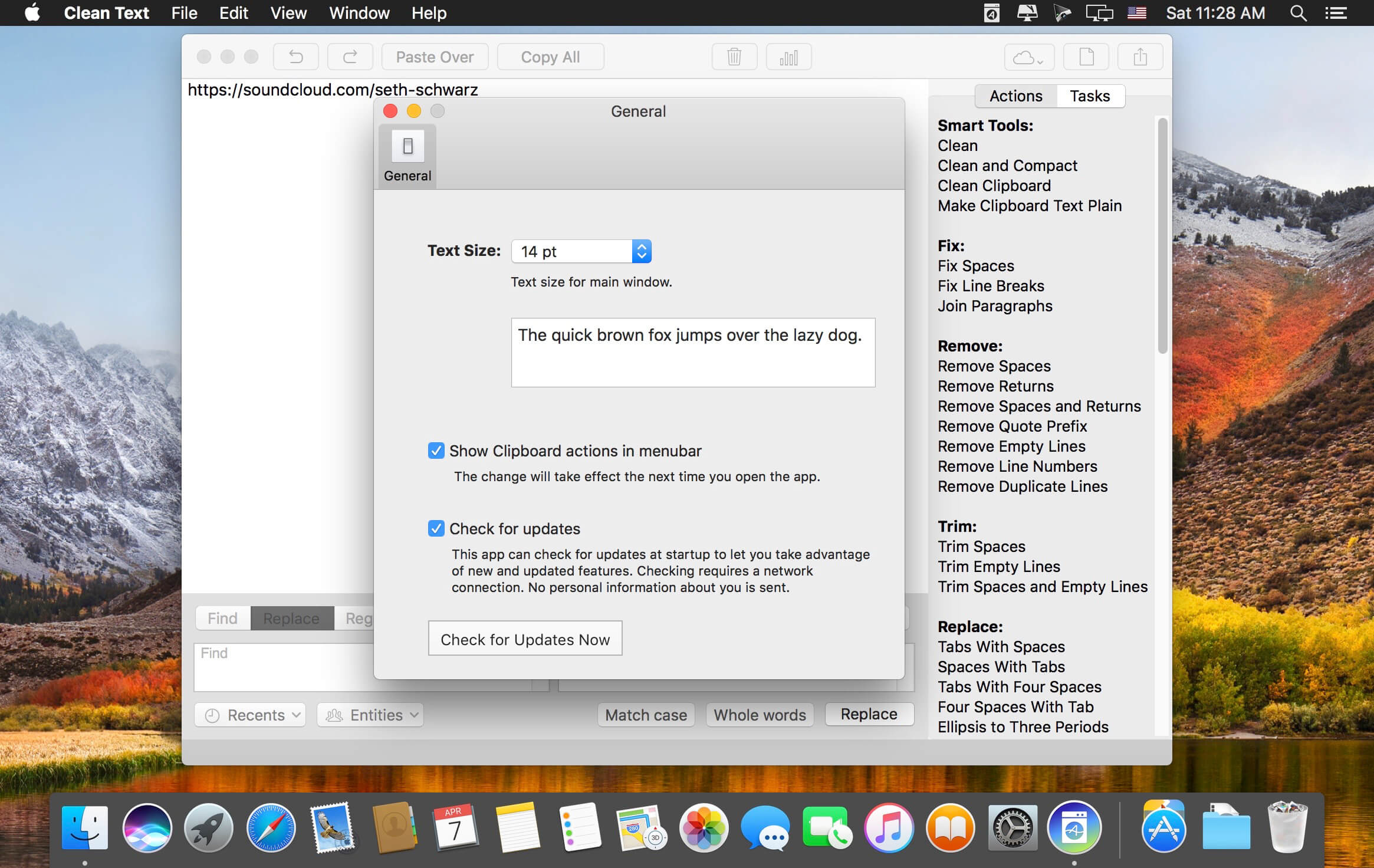

CLEAN TEXT SOUND FREE

leave a clean and dry surface, free from moisture or dry waste – e.g.The best cleaning requires a combination of important elements, as listed below. There are a range of strategies that have been proven to control the risk of slips, trips and falls, while also leaving floors and other surfaces clean and free from contaminants. incorrect cleaning products and procedures.poor, inappropriate or dirty cleaning equipment used.cleaning is ad hoc, unplanned and reactive.cleaning equipment and cords left across walkways.a build-up of cleaning product residues (reduces slip resistance).spills and contaminants are left unattended.floors are not fully dry and can be accessed.While good cleaning reduces contamination, bad cleaning increases contamination.Ĭheck your workplace for any of the signs that indicate a poor cleaning system:

CLEAN TEXT SOUND MANUAL

0 kommentar(er)

0 kommentar(er)